BY JAS ENGINEERING WASTEWATER TREATMENT SOLUTIONS FOR ABATTOIRS

By-Jas are specialists in the design and manufacture of wastewater treatment solutions for slaughterhouse and abattoir wastewater treatment.

By-Jas Engineering industrial wastewater solutions have the following advantages:

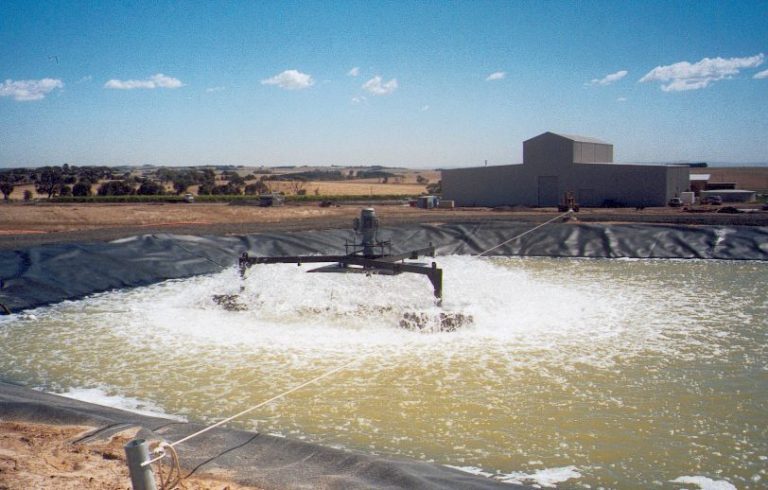

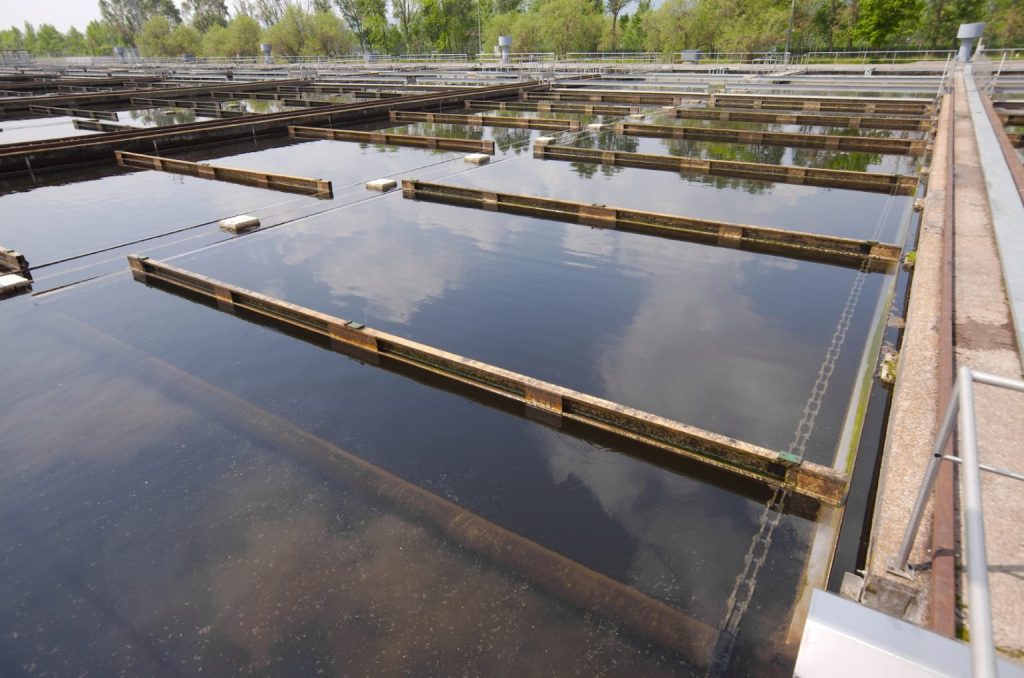

Our technical ability and experience make us the best choice for your project. We have a range of process technologies to deal with any type of meat processing wastewater. These include pre-treatment, dissolved air flotation, biological treatment, clarifiers, and disinfection.

- Low operation costs

- Automatic operation

- Low purchase price

- Process and effluent guarantees

Depending on the size of the production facility, the By-Jas Team can offer:

- a small compact mobile sewage treatment plant

- a retrofitting solution combined with using existing tanks

Application Description

Meat processing wastewater quality depends on water usage, the type of animal slaughtered and the amount of rendering or processing that is done on site. This industry includes abattoirs, slaughterhouses, meat packing companies and smaller butchers. Two distinct categories exist: red meat, which includes the processing of beef, mutton and pork, and white meat, for processing poultry. The wastewater contains high levels of blood, product remains and fats resulting in highly contaminated wastewater, which is often additionally contaminated by the delivery and intermediate holding of the animals for slaughter.

Wastewater Composition

The composition of wastewater from the meat processing industry are characterized by straw and saw dust, along with high concentrations of blood, fat and grease, animal body tissue (offal), animal trimmings, urine and faecal matter, as well as emitting smells. Each of these contributes to a high organic load as well as a considerable quantity of suspended matter.

Wastewater Charecteristics

The characteristics and volume of wastewater discharged from meat processing factories vary with the products and production procedures. Water plays a key role in Meat processing. It is used in every step of the technological lines, including cleaning and washing, disinfection, heating and cooling. Water requirements are huge.

Wastewater Categories

The three major categories according to their origin and composition are:

- Cleaning wastewater: Cleaning wastewater usually comes from washing equipment which is in direct contact with the products. These effluents are in large quantities and are highly polluted, thus requiring further treatment.

- Cleaning wastewater: Cleaning wastewater usually comes from washing equipment which is in direct contact with the products. These effluents are in large quantities and are highly polluted, thus requiring further treatment.

- Cleaning wastewater: Cleaning wastewater usually comes from washing equipment which is in direct contact with the products. These effluents are in large quantities and are highly polluted, thus requiring further treatment.

Case Studies

Over the past 20 years, the By-Jas Team has successfully designed many plants all over Australia. Examples vary from beef to poultry production.